Just How Laser Galvo Enhances Performance in Industrial and Medical Applications

Just How Laser Galvo Enhances Performance in Industrial and Medical Applications

Blog Article

A Comprehensive Overview to Galvo Motors and Their Influence On Laser Solutions

Galvo motors have actually emerged as an important component in the advancement of laser systems, providing enhanced precision and effectiveness throughout different applications. These tools facilitate fast positioning of optical components, which is vital for tasks varying from detailed engraving to complicated clinical procedures (Laser Galvo). As innovation developments, the assimilation of closed-loop control systems and expert system promises to press the boundaries of what these motors can attain. The implications of these advancements expand beyond plain efficiency improvements, elevating questions about future applications and industry improvements. What might this suggest for the landscape of laser technology?

What Are Galvo Motors?

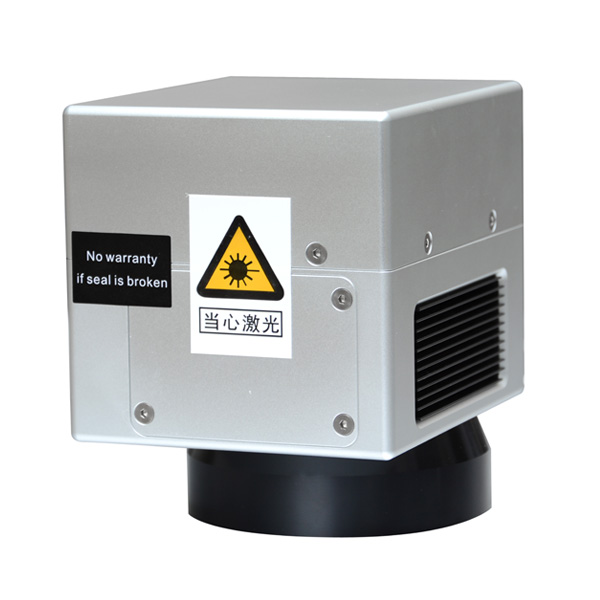

Galvo motors, brief for galvanometer motors, are accuracy devices made use of to regulate the setting of mirrors or lenses in laser systems. These motors are important to various applications, including laser inscription, cutting, and projection systems, where precise positioning is essential for ideal efficiency. Galvo motors use a lightweight layout that allows fast motion, enabling for high-speed procedure and exact control of laser light beams.

Additionally, galvo electric motors can be integrated with advanced control systems, permitting advanced programming and automation. This adaptability not just improves functional performance but also makes certain uniformity in output. Because of this, galvo motors have actually ended up being a vital element in modern laser innovation, promoting advancements in various areas by allowing precise adjustment of light with extraordinary speed and accuracy.

How Galvo Motors Run

The operation of galvo motors counts on precise electromagnetic systems that promote rapid and accurate positioning of mirrors or lenses. At the core of a galvo electric motor system are rotary coils placed on a shaft, which connect with magnetic areas generated by long-term magnets.

Galvo motors are defined by their closed-loop control systems, which make use of responses from position sensing units to guarantee precision. These sensing units monitor the angular setting of the mirrors, relaying data to the controller that readjusts the present provided to the electric motor. This feedback loop permits fine-tuning of the motor's setting, resulting in high repeatability and precision.

Furthermore, the lightweight construction of galvo motors lessens inertia, making it possible for fast action times vital for laser scanning applications. On the whole, the mix of electromagnetic principles and closed-loop comments systems makes it possible for galvo motors to do detailed tasks with remarkable precision and rate, making them important in innovative laser technologies.

Advantages of Galvo Motors

One of the crucial benefits of making use of galvo electric motors in laser systems is their capability to attain quick and specific positioning, which is critical for applications such as laser engraving, reducing, and scanning. This precision is greatly as a result of the high-speed feedback of galvo motors, allowing them to rapidly change the angle of the laser light beam with minimal delay.

An additional significant advantage is their lowered inertia compared to traditional stepper electric motors, which permits for quicker velocity and slowdown. This characteristic not only boosts the total rate of laser procedures but additionally adds to the top quality of the finished item by reducing activity blur.

Applications in Laser Solutions

Applications of galvo electric motors in laser systems extend a large range of industries, showcasing their adaptability and efficiency. Largely used in laser etching and noting, galvo motors allow accurate control over the laser beam's position, facilitating complex designs on various products such as check these guys out metals, plastics, and glass. Their rapid action times and precision dramatically improve production performance, making them vital in manufacturing procedures.

In the realm of laser cutting, galvo electric motors permit high-speed procedures, lowering the time needed for detailed cuts while maintaining side quality. This ability is especially beneficial in sectors like vehicle and aerospace, where precision is critical. In addition, galvo electric motors contribute in laser scanning applications, such as in 3D laser scanning and imaging systems, where they facilitate quick data procurement and evaluation.

Clinical applications additionally take advantage of galvo innovation, specifically in laser surgical procedure and diagnostic tools, where specific light beam control is critical for reliable results. On top of that, the introduction of laser-based micro-machining procedures has actually seen the fostering of galvo electric motors, enhancing the capability to perform fragile operations with unparalleled accuracy. On the whole, galvo motors play an essential function ahead of time laser innovation across varied areas.

Future Trends in Galvo Technology

Progressively, innovations in galvo modern technology are positioned to reinvent different sectors that depend on laser systems. One considerable trend is the view it now combination of synthetic knowledge (AI) and equipment knowing formulas into galvo control systems. These technologies boost accuracy and versatility, permitting real-time modifications based upon vibrant ecological conditions or product properties.

An additional emerging trend is the advancement of higher-speed galvo motors, which help with faster processing times in applications such as laser inscription and cutting - Galvo. As sectors demand quicker turnaround times, these technologies will become crucial for maintaining affordable advantage

In addition, miniaturization of galvo components is making laser systems a lot more small and functional. This fad is especially pertinent in markets such as clinical tools, where room restraints are vital.

Verdict

Galvo motors have arised as a critical component in the advancement of laser systems, supplying boosted precision and performance across various applications.Galvo electric motors, brief for galvanometer motors, are accuracy devices made use of to manage the setting of mirrors or lenses in laser systems. Mainly made use of in laser etching and marking, galvo electric motors allow exact control over the laser beam of light's setting, promoting elaborate layouts on various materials such as metals, plastics, and glass. Galvo motors are crucial in laser scanning applications, such as in 3D laser scanning and imaging systems, where they help with fast information procurement and evaluation.

As innovations in closed-loop control systems and man-made intelligence integration proceed to progress, the potential for galvo motors to further change laser systems remains significant, promising increased speed and minimized motion blur, consequently broadening their utility across varied commercial sectors.

Report this page